We are presently also on the market for air duct making machine, such as auto duct production line, lock forming machine, shearing machine, flange forming machine, bending machine etc.

The application of this kind machine is: Air duct manufacture in industries of central air conditioning, ventilation duct, muffler, dust project, oil insulation, purification system etc.

TDF flange Machine (Total plate flange machine)

Introduction

Our company’s TDF machine is the special equipment to process various kinds of square and rectangular ventilation pipelines. It has strong function and can satisfy the bone shape connecting in wind pipe manufacturing. It has models of T-12 and T-15. The processing thickness: 0.5-1.2mm; 0.8-1.5mm. All the axes and clamping rollers on this machine are manufactured by high quality steel and advanced industrial heat treatment technology which will greatly increase the wear resistance life of the parts.

Features

This machine is main equipment for TDF flange forming, especially for large-scale, standardized and automatic production.

Both flanges and L-shaped clamp can be produced synchronously.

Material feed automatically while sheets processed.

All rollers and bearings adopt excellent steel processed by advanced heat treatment technology (quenching), which enhances wear-resistance for the machine.

14 Groups of rollers form a stable and beautiful shape.

Pressure bearings are being used to avoid the side wear.

Specifications

|

Model |

Power |

Plate thickness

(mm) |

Shape |

Size

(mm) |

Weight

(kg) |

Dimension

(mm) |

|

T-12 |

2.2 |

0.5~1.2 |

|

32+-0.5 |

1000 |

2900*700*1100 |

|

T-15 |

4 |

0.8~1.5 |

|

32+-0.5 |

1200 |

2900*700*1100 |

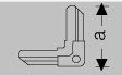

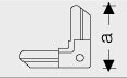

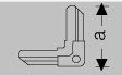

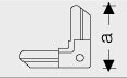

Optional Corner Mould

|

Model |

Name |

Capacity

(mm) |

“a”size

(mm) |

Sample |

|

T-10DC |

Duct corner |

1.0 |

a=95 |

|

|

T-15DC |

Duct corner |

1.2 |

a=95 |

|